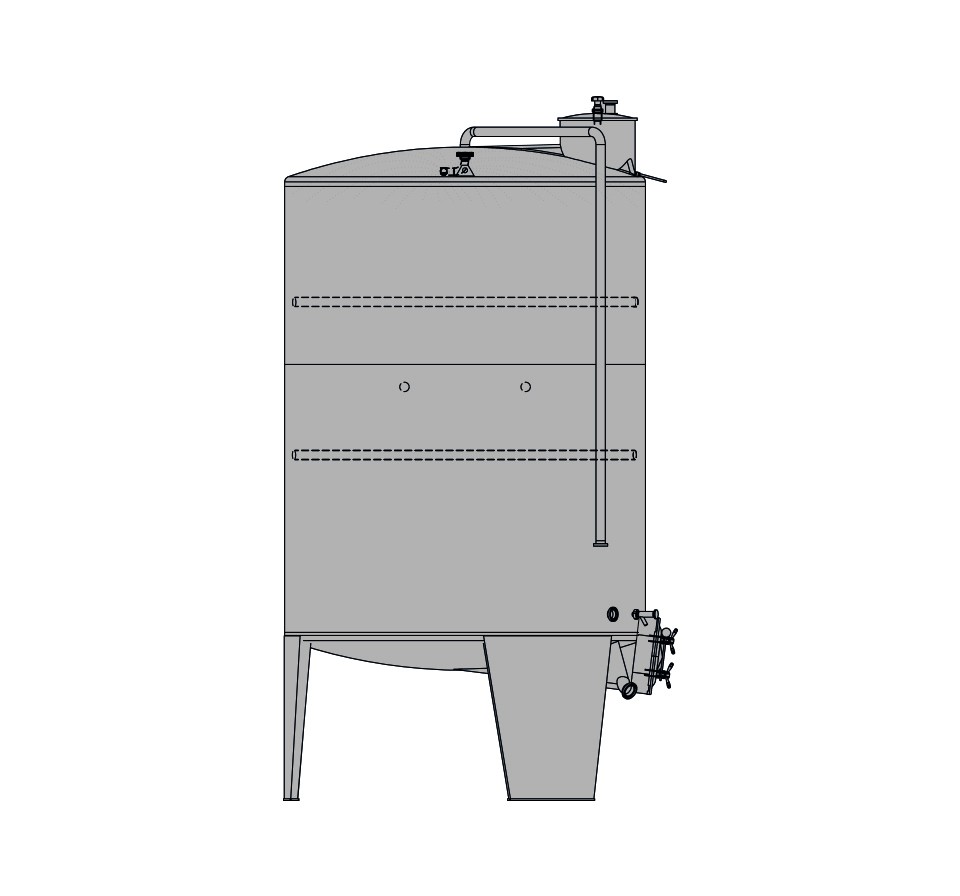

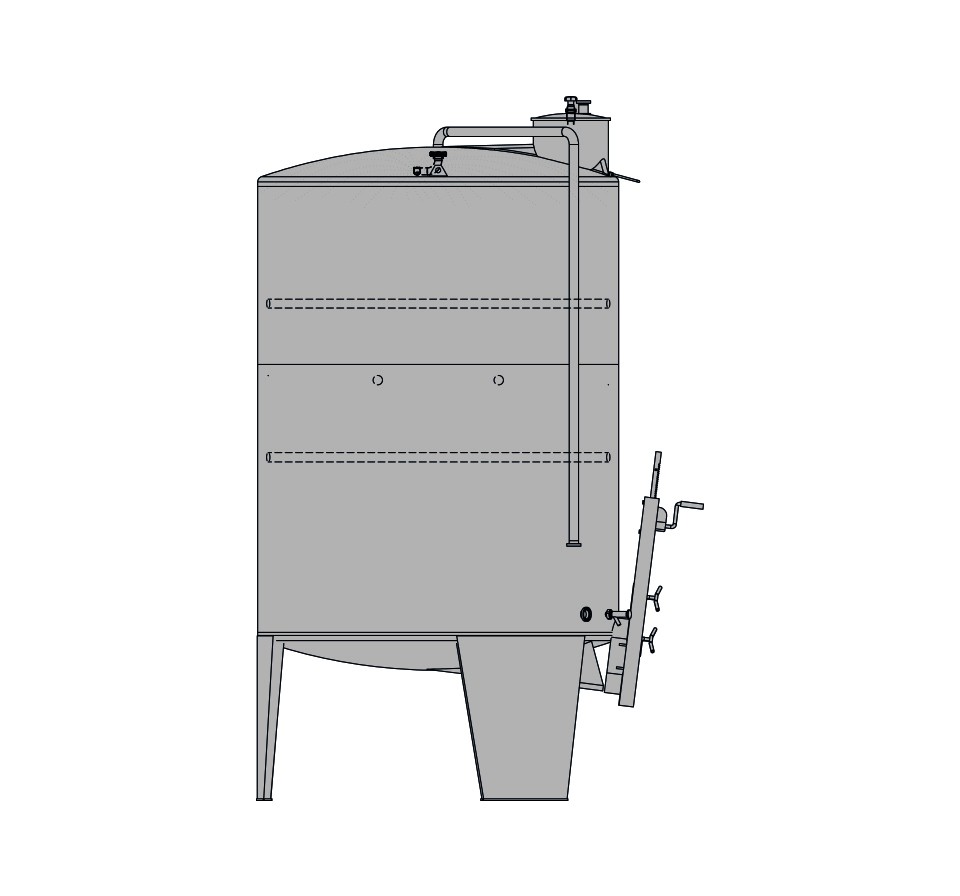

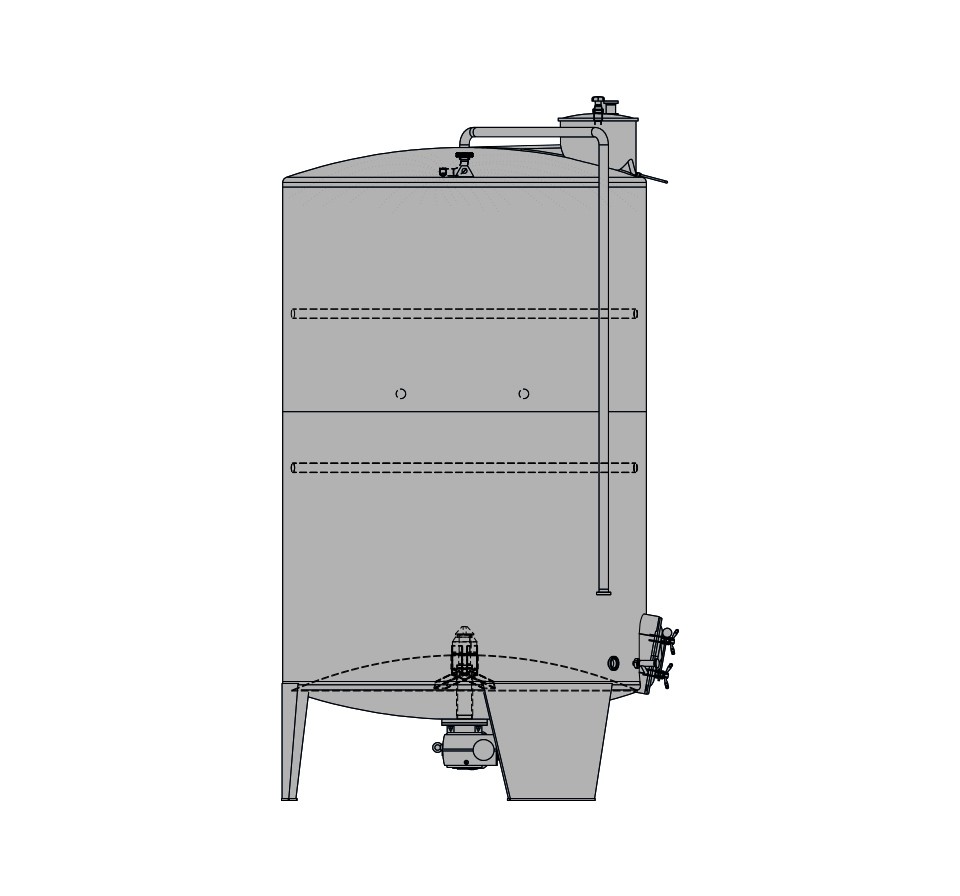

Description

The tank is an upright standing wine fermentation. After the fermentation has started and a marc cake has been formed. The cake comes down to the ground, breaks into pieces and is ‘opened’ by a system of rods.

Afterwards the juice is pumped in again via a self-rotating sprinkling system and the smashed marc cake is flooded. The pigments are washed out. This procedure is repeated several times. The principle of the ‘reassembly’ or reassembly has been practiced successfully all over the world.

Standard accessories

TANK TOP

-

Up to tank-ø of 2,000 mm made of AISI 316 stainless steel, surface IIId (2R), marbled outside

-

From tank-ø of 2,200 mm upwards made of AISI 316 L / 316 stainless steel surface IIId (2R) / IIIc (2B)

-

Ladder safety bow, jack rings

TANK SHELL

-

Made of AISI 304 stainless steel, surface IIId (2R), marbled outside

TANK BOTTOM

-

Up to tank-ø of 2,000 mm made of AISI 304 stainless steel, surface IIId (2R), marbled outside

-

From tank-ø of 2,200 mm upwards made of AISI 304 stainless steel, surface IIId (2R) / IIIc (2B)

-

Free-standing on welded-on box-shaped legs perfect stability and force transmission into the tank

FILLER NECK

-

Filler neck NW 400, located in tank top with an upright forward position (tank top with bead extrusion for complete ventilation)

-

Flap lid with vent neck NW 50 Rd 78 x 1/6″

TEMPERATURE MEASUREMENT

-

Weld-on thread NW 10 DIN

-

Threaded sleeve with locking screw and cap nut NW 10 DIN

-

Bi-metal dial thermometer 100 mm ø, measuring range – 20 ° to + 60 °C

SAMPLING

-

Weld-on thread NW 20 DIN

-

Sampling tap with cap nut NW 20 DIN

RACKING OUTLET

-

Reinforcing plate with drilled hole 48 mm ø (to hold flap valve Gr. 37 or weld-on thread NW 50 DIN )

JUICE FLOODING

-

Stainless steel pipeline NW 50 with self-rotating sprinkling system

-

Connecting thread NW 50 DIN , from ø 2,800 mm upwards with 2 flooding heads

MARC BREAKERS

-

Horizontally staggered moulded pipes break the descending marc into pieces

JUICE TOTAL OUTLET / -FILLING

-

Welded-on neck with thread NW 65 DIN