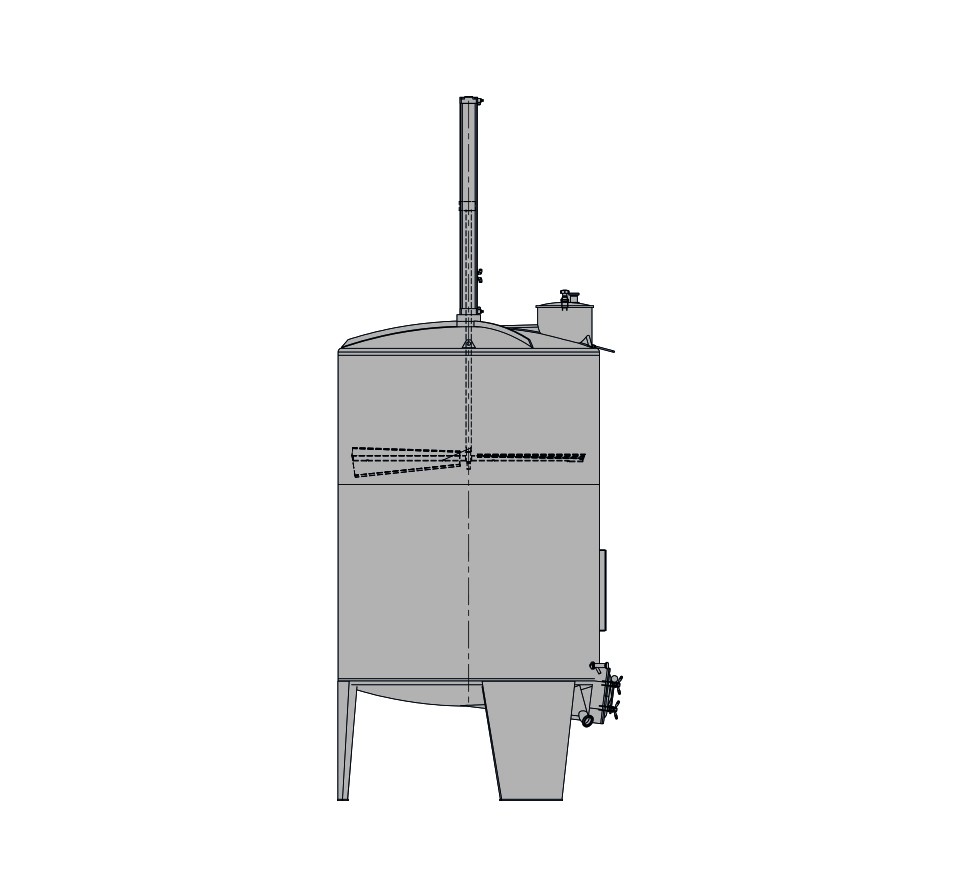

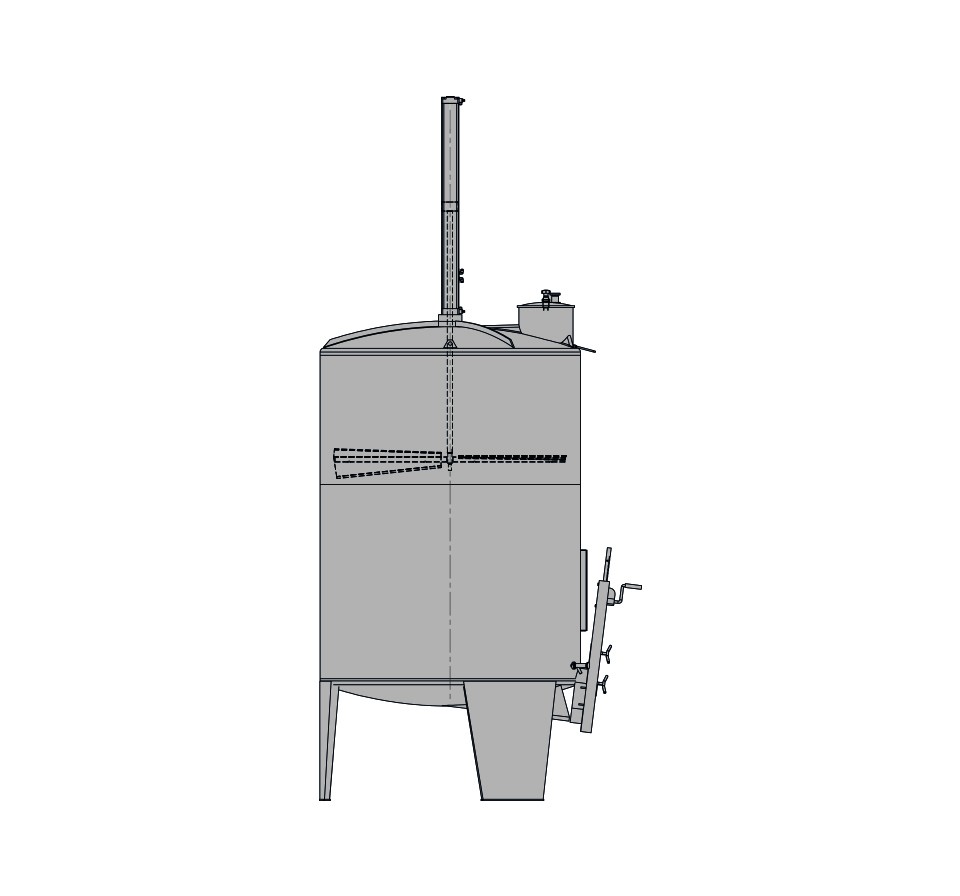

Description

A reinforced pneumatic cylinder moves the immersion unit up and down. At the moment of the immersion, namely when ‘impacting’ the marc, two cone-shaped folding wings facing each other put themselves in a flat position and immerse the grapes into the juice.

When moved upwards the folding wings adopt an inclined position and generate a twisting effect of approx. 30 °. This is repeated until the entire marc is fully disintegrated, immersed and drenched with the must.

The immersion and interval times can be pre-selected at your convenience. This grants the winemaker the opportunity to produce individual and complex red wines. The system itself is simple and highly effective: spacious installations that could cause sedimentary depositions or dirt corners are not required.

Standard accessories

TANK TOP

-

Up to tank-ø of 2,000 mm made of AISI 316 stainless steel, surface IIId (2R), marbled outside

-

From tank-ø of 2,200 mm upwards made of AISI 316 stainless steel, surface IIId (2R) / IIIc (2B)

-

Ladder safety bow, lifting lugs

TANK SHELL

-

Made of AISI 304 stainless steel, surface IIId (2R), marbled outside

TANK BOTTOM

-

Up to tank-ø of 2,000 mm made of AISI 304 stainless steel, surface IIId (2R), marbled outside

-

From tank-ø of 2,200 mm upwards made of AISI 304 stainless steel, surface IIId (2R) / IIIc (2B)

-

Free standing on welded box-shaped legs

FILLER NECK

-

Filler neck NW 400, located in tank top with an upright forward position (tank top with bead extrusion for complete ventilation)

-

Flap lid with vent neck NW 50 Rd 78 x 1/6″

TEMPERATURE MEASUREMENT

-

Weld-on thread NW 10 DIN

-

Threaded sleeve with locking screw and cap nut NW 10 DIN

-

Bi-metal dial thermometer ø 100 mm, measurement range - 20 °C to +60 °C

SAMPLING

-

Weld-on thread NW 20 DIN

-

Sampling tap with cap nut NW 20 DIN

RACKING OUTLET

-

Reinforced plate with drilled hole ø 48 mm (to hold flap valve or weld-on thread NW 50 DIN 11851)

JUICE TOTAL OUTLET / -FILLING

-

Welded-on neck NW 65 DIN

MASH IMMERSION SYSTEM

-

Electronic control system (Stainless steel control cabinet, by default located on the right), Connection 220 V, 50 Hz

-

Immersion time and pause time inverter controlled

-

Pneumatic cylinder flange mounted on the reinforced top

-

Piston rod and immersion unit made of stainless steel