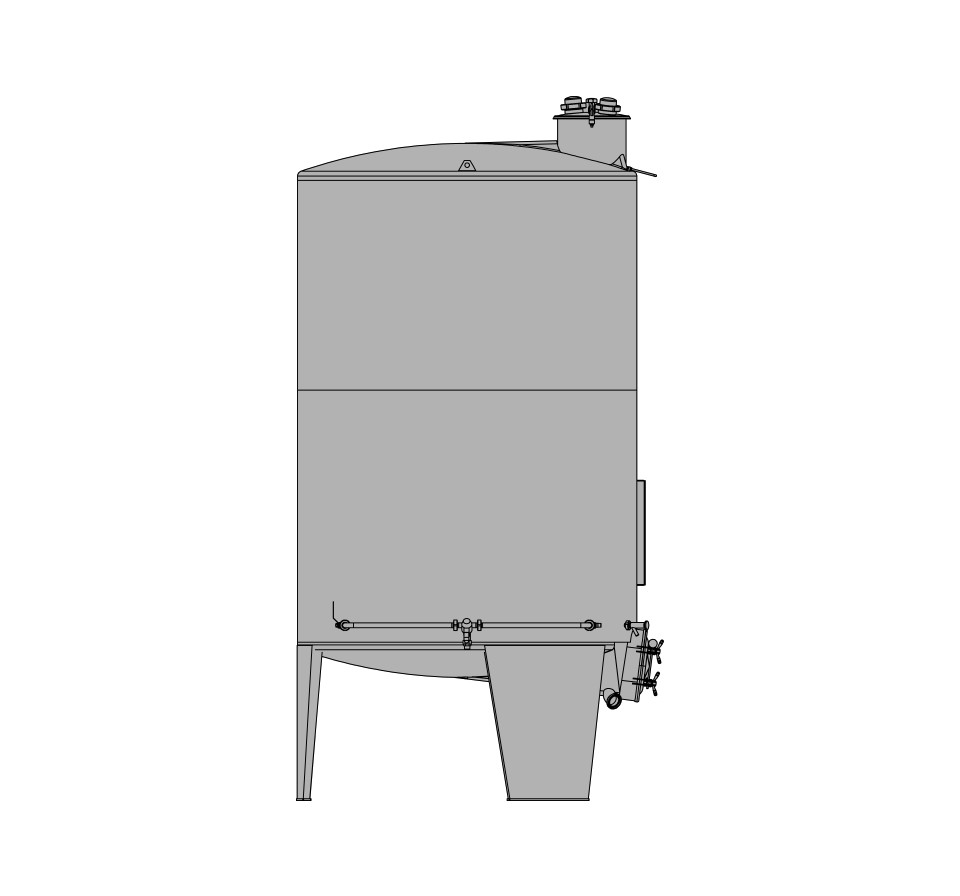

Description

Over the last years a constant development of quality-improving technologies to obtain a possibly high aroma and lots of colour from the berries has taken place. In the meantime the fundamental understanding of the direct contact of wine with aerial oxygen has been defined in a new way. Once being partly defined as ‘the enemy of wine’, air can however – at least in certain phases of the fermentation and maturation process – cause positive effects on the wine.

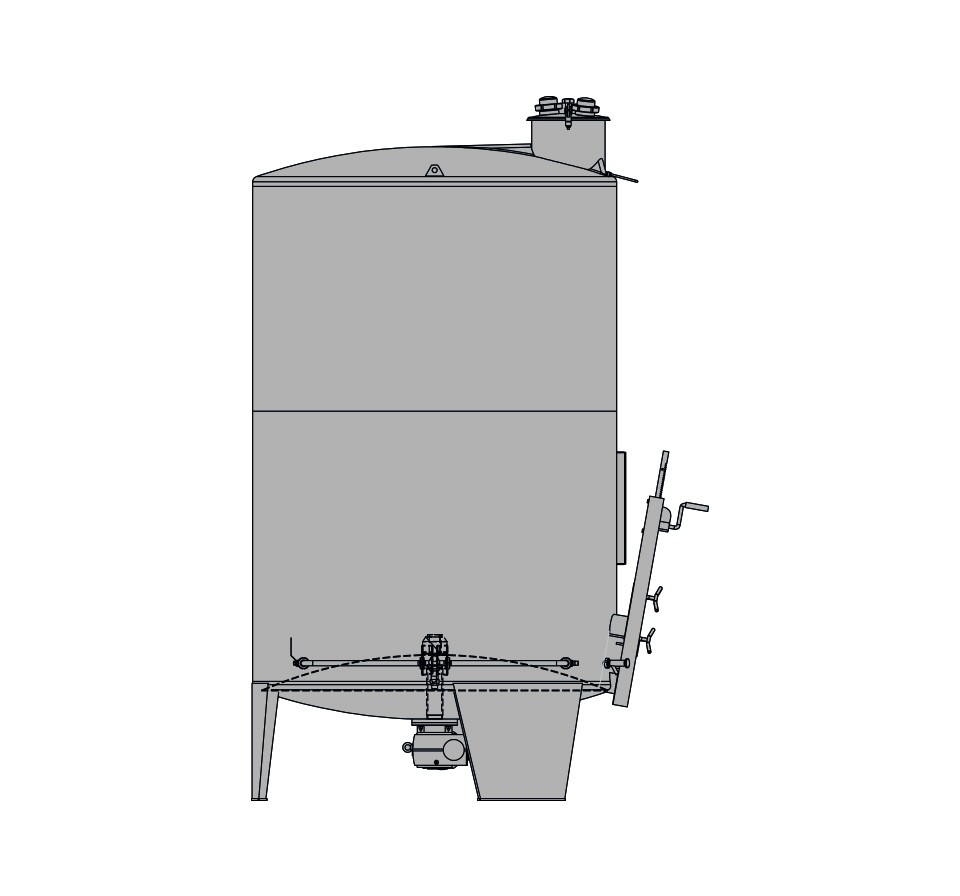

This is why we have developed a mash fermentation tank that penetrates and gently mixes the emerging marc by means of air jets that use purified pressurised air during the process of fermentation. This way we combine a gentle type of re-circulation with intensive air contact during the main fermentation phase.

The tanks are equipped with 4 lateral air impulse jets that are safeguarded by non-return valves.

An electronic control system regulates the intervals of the injections. This way injections that mix the marc cake can be released in specific time intervals during the mash fermentation. For approx.

15 seconds jets release air at an air-pressure of 6 to 8 bar. As a result, the CO2 is released from the grapes, thus leading to a regroupment of the mash.

The mash is washed over with the wine and mixed at the same time. The grapes end up in a new position which allows for a better extraction of both colour and aroma. The air released into the tank can escape through valves at the tank’s top. The pressure flooder is an economic option for the gentle mash fermentation of top-quality red wines with intense fruit shades and early mature character. We recommend to additionally equip this system with the flooder option.

Standard accessories

TANK TOP

-

Up to tank-ø of 2,000 mm made of AISI 316 stainless steel, surface IIId (2R), marbled outside

-

From tank-ø of 2,200 mm upwards made of AISI 316 stainless steel, surface IIId (2R) / IIIc (2B)

-

Ladder safety bow, lifting lugs

TANK SHELL

-

Made of AISI 304 stainless steel, surface IIId (2R), marbled outside

TANK BOTTOM

-

Up to tank-ø of 2,000 mm made of AISI 304 stainless steel, surface IIId (2R)

-

From tank-ø of 2,200 mm upwards made of AISI 304 stainless steel, surface IIId (2R) / IIIc (2B)

-

Free-standing on welded-on box-shaped legs

FILLER NECK

-

Filler neck NW 400, located in tank top with an upright forward position (tank top with bead extrusion for complete ventilation)

-

Flap lid with vent neck NW 50 Rd 78 x 1/6″

TEMPERATURE MEASUREMENT

-

Weld-on thread NW 10 DIN

-

Threaded sleeve with locking screw and cap nut NW 10 DIN

-

Bi-metal dial type thermometer 100 mm ø, measuring range – 20 ° to + 60 °C

SAMPLING

-

Weld-on thread NW 20 DIN

-

Sample tap with cap nut NW 20 DIN

RACKING OUTLET

-

Reinforcing plate with drilled hole 48 mm ø (to hold flap valve Gr. 37 or weld-on thread NW 50 DIN )

PRESSURISED AIR SYSTEM

-

4 removable, individually lockable jets are laterally arranged at the tank

-

The jets provide the air impulses for the mixing of the mash.

JUICE TOTAL OUTLET / -FILLING

-

Welded-on neck NW 65